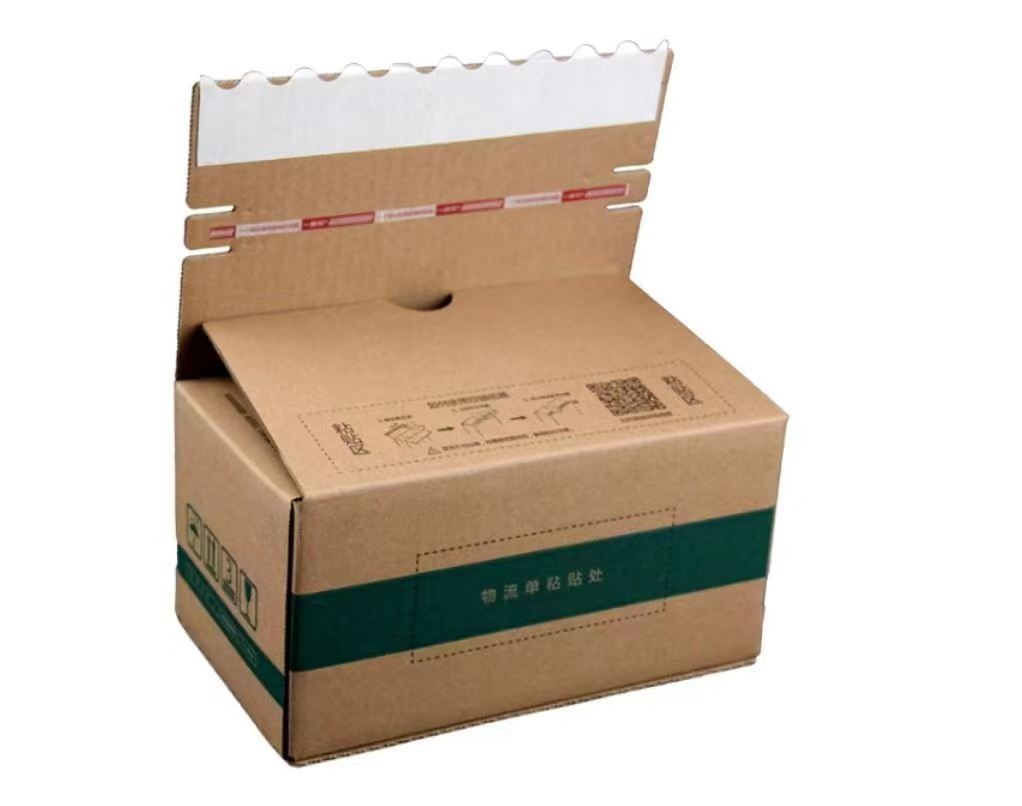

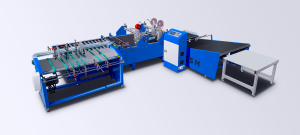

Automatic double tape application Machine

Automatic double-sided adhesive tape machine is fast to change order.Normally it only need 5-10 minutes to make it run again. No need to disassemble the applicators when change the double side tape. It mainly includes the below Parts.

Feeder Section

Sticking Table

Controller System

Conveyor Section

To get more details about our Carton box Smart equipments, pls visit here

Detailed parameters

| Material: | More than 300 g/m² Cardboard E -, B -, three layer and five layer corrugated paper |

| Open blank: | Min. 250 mm x250 mm |

| Max. 1800 mm x1800 mm | |

| Working width: | 1800mm |

| Conveyor speed: | 70 m/min (the actual production speed depends on the paper material and box type) |

| Tape roll width: | Easy tear tape 4-8mm, double-sided adhesive tape 5-40mm |

| Precision: | +/- 2mm (different performance according to double-sided adhesive tape and box type) |

| Sticking style: | Longitudinal gluing |

| Number of installable tape applicators: | 1 easy tear tape applicator, 2 sets of double-sided adhesive applicators |

| Needed air supply: | Min. 6 bar |

| Power required: | 8.5KW(380V AC 3φ 50HZ) |

| Weight: | 3200KG |

| Machine Size: | 8200*2200*1250m(L*W*H) |

Main electrical component

| order | name | brand |

| 1 | Main Motor | CHENGBANG |

| 2 | Calibration Motor | CHENGBANG |

| 3 | Feeder Motor | CHENGBANG |

| 4 | Main Motor Frequency Inverter | PANASONIC |

| 5 | Calibration Frequency Inverter | PANASONIC |

| 6 | Feeder Frequency Inverter | PANASONIC |

| 7 | Controller System | MITSUBISHI |

| 8 | Photoelectric Sensor | KEYENCE |

| 9 | Main Drive Bearing | NSK、SKF |

| 10 | Electromagnetic contactor | SCHNEIDER |

| 11 | Applicator The electromagnetic valve | SMC |

| 12 | Cylinder | SMC |

| 13 | Safety relay | SCHNEIDER |

| 14 | Contactor | SCHNEIDER |

Note:The above 14 items are important parts

Detail Introduction

|

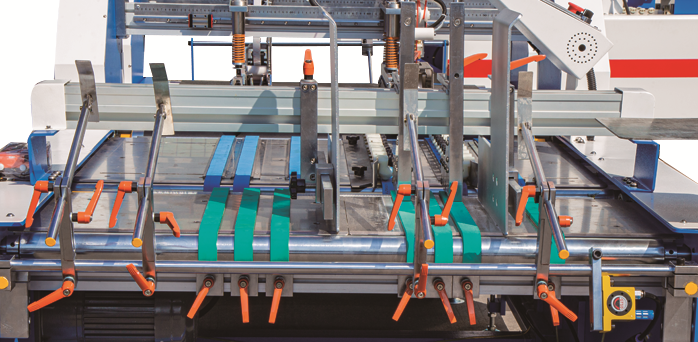

Calibration Section |

|

|

This part just uses the roller construction with new calibration part. Keep one box side as the base and ensure the products in the same line when running.

|

|

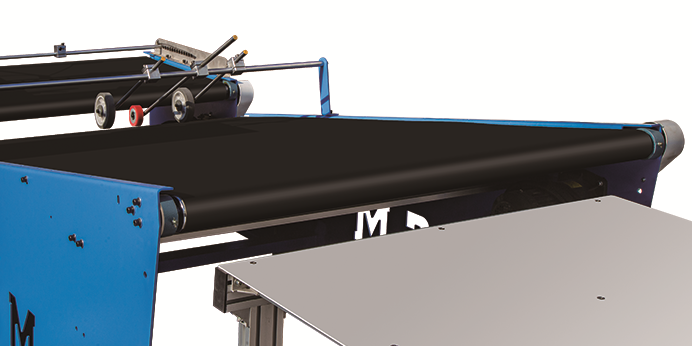

Conveyor Section |

|

| It uses the stack collection structure design and the 2mm thickness belt(imported ) is soft enough to protect the products from pressing damage, and make sure their perfect quality

|

|

Write your message here and send it to us