Auto Key strapping machine

This machine if not suitbale,pls visit here

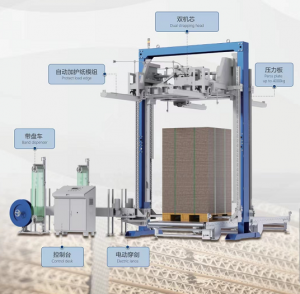

Auto Rotation Top Packing machine with pressing device:

Feature and Advantage

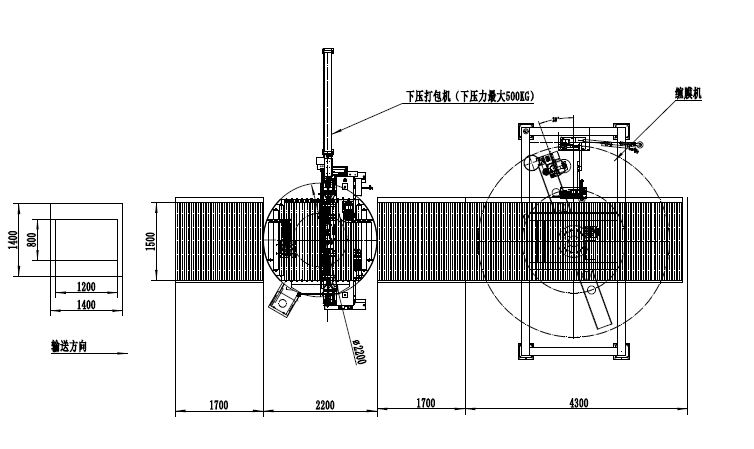

• Packing size: Length1400-1200x width1200-800x height 1800-2100mm (including pallets)

• Be equipped with high-performanc, high-frequency friction movement, the joint is stable, without maintenance of hot knife

• The main frame is composed of two bending columns and cross beams. The guide device is a solid guide shoe, equipped with a frequency converter, and the operation and braking are stable

• Balancing force system, more uniform and balanced force at four corners

• Independent packing belt distributor with turning, wire rail drive, electromagnetic brake and buffer device can effectively prevent the packing belt from being damaged.

• Integrated electric drive sword piercing system, frequency conversion control, reliable, and no need maintenance.

• The control system and human-machine interface based on Siemens S7-200SMART.

Tech Parameter

|

Items |

Parameter

|

Note

|

|

Power |

3000W |

|

|

Power supply |

3-phase 5-wire AC 380V/50Hz |

|

|

Press air consumption |

No need |

|

|

Gross weight |

1330KG |

|

|

Net weight |

1040KG |

|

|

Scope of pallet lode size |

(1200-1400)*(800-1200)*(1800-2100)mm |

Customized |

|

Minimum cargoheight |

100mm |

|

|

Strapping force |

200-250KG(200-2500N) |

|

|

Compression force |

500kg |

|

|

Band material |

PET |

|

|

Band type |

Width:16 Thickness:0.7-0.9mm 406 inner diameter of paper core, 20KG/roll Inner diameter of paper core, 20KG/roll |

|

|

Joint type |

Friction welding/85% (female strip) |

The interface strength depends on the tape quality |

|

Packing drive type |

Electrical |

|

|

Strapping cycle Speed |

30 t/h Pallets/hour |

Single machine efficiency |

|

Tape spacing |

Customized |

|

|

Packing height |

As per height of production line |

|

|

Joint position |

Top |

|

| Belt feeding position |

Any height |

|

|

section size |

60*51 |

Space requirement:80mm*80mm |

|

Interface |

Ethernet |

|

|

Traverse Lift type |

Rack&gear |

|

|

Mechanical and electrical configuration. |

||

|

Items |

Date |

Note |

|

Touch screen |

Siemens |

|

|

PLC |

Simens S7-200s |

|

|

Frequency converter |

Schneider |

|

|

Circuit breaker |

Schneider |

|

|

Contactor |

Schneider |

|

|

Terminal |

Youtile |

|

|

Cable |

Cardiff |

|

|

Safety relay |

Omron |

|

|

Limit switch |

Omron |

|

|

Photoelectric switch |

Omron |

|

|

Main lift motor |

Chinese Famous brand |

|

|

Bear |

Chinese Famous brand |

|

|

Ball bearing |

Renben |

|

|

Energy chain |

CPS |

|

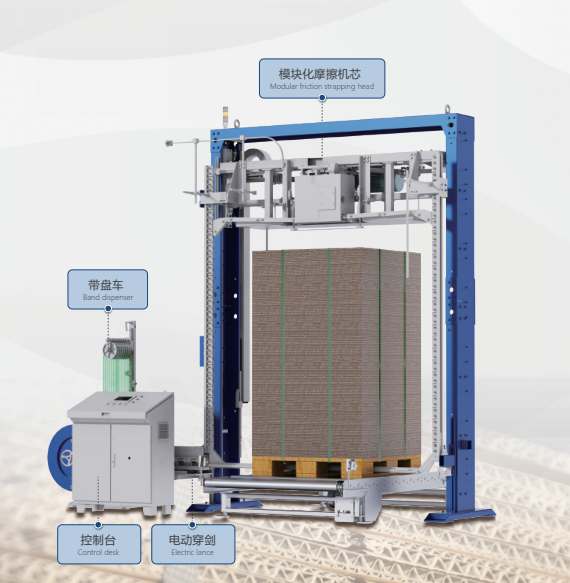

Auto Key threading packing machine:

1-1. Equipment shape (length*width *height):Customization; (subject to the final drawing)

1-2. The effective size of the arch (width*height): Customization;

1-3. Equipment power/voltage: 2.5KW/380V 50hz

1-4. Applicable strapping straps: PET machine straps (16mm*0.6mm PET strapping straps for fully automatic machines);

1-5. Binding method: # Four;

1-6. Heating method: electric direct heating;

1-7. Tightening method: secondary tightening, fixed length to control the tightening force;

1-8. Threading method: electric;

1-9. Movement mode of movement: electric type, frequency conversion speed regulation, effective movement stroke of movement 600mm; (non-complete machine movement, movement of movement alone, to maximize work efficiency and reduce mechanical failures)

1-10. Control mode: automatic and manual switching between each other at will, equipped with emergency stop safety control buttons;

1-11. Control interface: using button control, with manual, start, pause, emergency stop, pass and other functions;

1-12. Packing speed: 20-22 seconds/piece; (including the completion of the packing action of the whole machine)

1-13. It has its own fault detection function, and through the warning lights installed outside, it can prompt and alarm;

| Auto Key threading rotation Packing machine | Name | Brand |

| PLC | Mitsubishi | |

| Inverter | Delta | |

| AC Contactor | Schneider | |

| Overcurrent protector | ||

| Switch button | ||

| Indicator | ||

| Proximity switch inside the movement | Autonics/Han Rong | |

| Limit switch | Omron | |

| Intermediate relay | Schneider | |

| breaker | Schneider | |

| Machine head drive motor | Shengbang | |

| pneumatic | AirTAC |