China Supplier Pallet Conveyor System - Auto Module Belt Conveyor System – GOJON

China Supplier Pallet Conveyor System - Auto Module Belt Conveyor System – GOJON Detail:

Auto conveyor system can meet different requirements of corrugated cardboard conveying of different widths and lengths. The modular belt conveyor platform, modular belt electric distributor, modular belt XY turner, and Auto roller conveyor line can all be designed according to customer’s idea. For example, one manufacturer who is specializing in the production of cardboard, no need to reprocess the cardboard, and the cardboard can be shipped after packaging, and the logistics system is relatively simple. The stacks of paper output by the stacker are transported to multiple docks in turn by the electric sorting car. Workers complete the package of cardboard at the docks. The entire transporting process of the stacks can be completed automatically or manually. The logistics system runs smoothly, high efficiently. For manufacturers with printing capabilities in the factory, the cardboard produced is directly forwarded to the next production process: die cutting, printing, box gluing, box nailing, and storage. In order to relieve the pressure of paper pallet transportation, such manufacturers need to design the entire plant logistics.

Intelligentized Cardboard Conveyor System

1. Reducing labor cost

2. Facilitating operation

3. Satisfying the needs of the modern enterprise’s production and management

Conveyor System on the Buffer Zone

With the optimization of purchase orders and the upgrading of the speed of the line, the existing storage mode can’t satisfy the demand of the production capacity. However, GOJON software greatly expands the storage space, lowers the cost of transportation, improves the operating efficiency, ensures the tidiness & orderliness of the workshop and enables the limited storage space to create infinite value.

The Feed-in and Feed-out on the Processing Area

In response to the constant upgrading of printing machine and die-cutting machine, GOJON conveyor system solved the problems of human handling fatigue and low conveying efficiency, To make processing equipment develop efficient capacity of printing machine and die-cutting machine, realize the intelligent operation on the processing area.

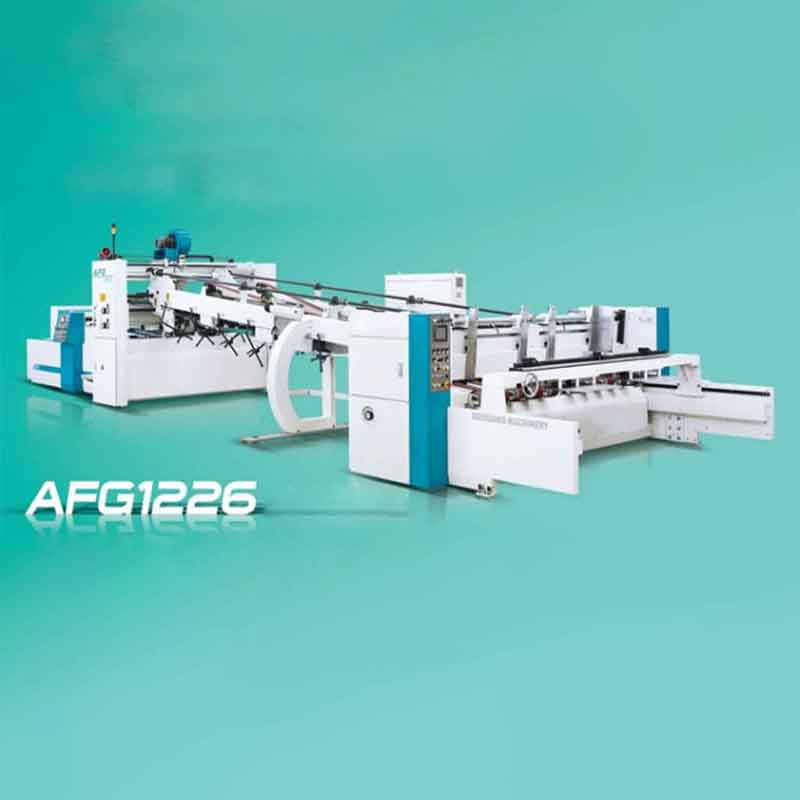

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for China Supplier Pallet Conveyor System - Auto Module Belt Conveyor System – GOJON , The product will supply to all over the world, such as: Japan, Morocco, Slovenia, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have now the already penetrated. On account of superior quality and competitive price , we'll be the market leader, be sure to don??¥t hesitate to contact us by phone or email, if you are interested in any of our solutions.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.