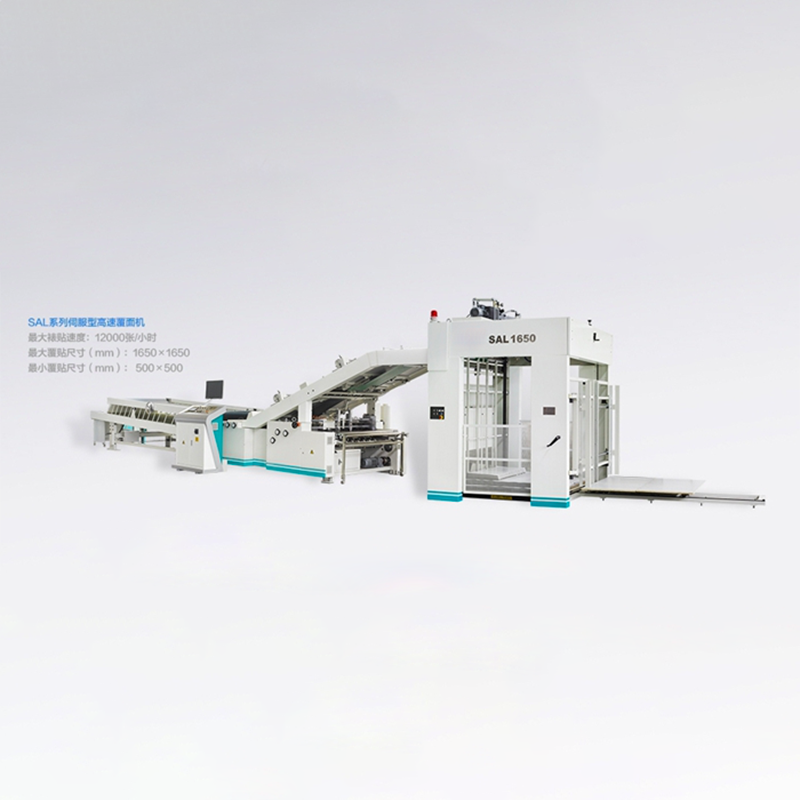

China wholesale Single Facer Corrugator Line - Single Facer Laminating Smart Line – GOJON

China wholesale Single Facer Corrugator Line - Single Facer Laminating Smart Line – GOJON Detail:

Feature

* Work with both offset and preprinted paper, there is no need to replace any machine each other, reduce the cost obviously.

* Both PVA and starch glue can be used in the laminating

* Cassette single facer is equipped with electrical trolley, quick changing corrugated rolls.

* High speed splicer, non-stop splicing, less waste

* Non-stop changing order system for the top sheet stack

* corrugated cardboard Humidification system, flatten board, adjusting humidity

* corrugated cardboard trimming, automatic waste discharge.

* Servo synchronous cutting machine, color detection, accurate positioning of fixed length.

* Servo motor high speed laminator, automatic synchronous for top and bottom sheet.

* High speed stacker, automatic rotary stacker.

* Video monitoring on the main control panel, timely detection of equipment anomalies.

* Production management system, improve efficiency, increase production, reduce loss.

* Equipped with remote diagnosis system for machine maintenance.

Parameters

* The maximum effective width of cardboard:1650mm

* The minimum effective width of cardboard:600mm

* The maximum effective size of cardboard(length X width): 1650mmX 1650 mm

* The minimum effective size of cardboard(length X width): 500mm X 600 mm

* The maximum mechanical liner speed:150m/min

* The maximum laminating speed:12000P/h

* Single piece laminating Accuracy: ±1mm(front)、±0.5mm(side)

* Paper roll positioning crosscutting accuracy: ±1mm

* Maximum stacking speed :12000P/h(E Flute)10000P/h(B flute)

* Stacker height:1800mm(with pallet)

* Installed capacity:202kW

* Machine dimensions(Length X Width X Height):63000mmX5340mmX4530mm

* Machine required plant size(Length X Width X Height): 68000mmX10500mmX4530mm

Accessories Appendix

| Name |

Brand |

| Corrugator roll | Yuan lu, RMM (Da song), Boli |

| Bearing | Japan NSK, USA TWB |

| Rotary joint | Tengxuan |

| Diaphragm pump | USA Inger-soll rand |

| VFD motor | Taiwan Dongyuan |

| Main electrical parts brand | Rexroth, Omron, Schneider, AB, Danfoss Siemens |

| Hydraulic system | Taiwan Seven Ocean |

| Pneumatic components | Taiwan Airtac or Mindman |

Product detail pictures:

Related Product Guide:

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for China wholesale Single Facer Corrugator Line - Single Facer Laminating Smart Line – GOJON , The product will supply to all over the world, such as: Panama, Stuttgart, Sevilla, Our company always provides good quality and reasonable price for our customers. In our efforts, we already have many shops in Guangzhou and our products have won praise from customers worldwide. Our mission has always been simple: To delight our customers with best quality hair products and deliver on time. Welcome new and old customers to contact us for the future long term business relationships.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!