Factory directly supply Scientific Inventory Control System Exercise Control - PMS and RFID paper roll storage management – GOJON

Factory directly supply Scientific Inventory Control System Exercise Control - PMS and RFID paper roll storage management – GOJON Detail:

Synchronization Control

The synchronization means control single facer speed, it can keep same speed with the main canvas belt. Its role is to avoid excessive paper accumulation or pull off the bridge paper. Because speed rapid change, easy to shake machine, poor corrugated flute, poor bonding and other issues; health management will be based on characteristics of the individual motors at different speeds to provide different speed control curve, try to slow down the speed change, and get stable corrugated flute and glue (paste) uniform.

Overhead Bridge Paper Accumulation Control

Overhead bridge control, not only to avoid the paper cutter and paper accumulation problems, and affect the accuracy of the entire wet paper change and manual tear sheet automatic compensation.The reason is simple, the entire production line, in addition to the paper wavy bridge plot is not easy to estimate, but the distance is almost fixed data from mill roller to climbing belt, as well as from the bridge suction paper guide to NC cutter. Really want to count, it is how to calculate the actual volume of paper bridge, as well as the amount of automatic detection compensation for doing bad paper torn by worker on the bridge.

For bridge detection and control, tracking and flow control technology; the one hand, track actual paper accumulation, on the other hand, use climbing belt feed amount and bridge suction guide paper output amount, to measure by flow control. The difference between the two amounts (bridge tear amount) feedback synchronization control automatically, to achieve compensation and a fixed bridge accumulation.

Auto Splicer Control

Automatic splicing machine is not only connected to the control at the appropriate time, it also includes bridge accumulation, synchronous, slow down, before splicing paper, and paper control from paper head feed into the corrugating roll till recovery etc, series of control

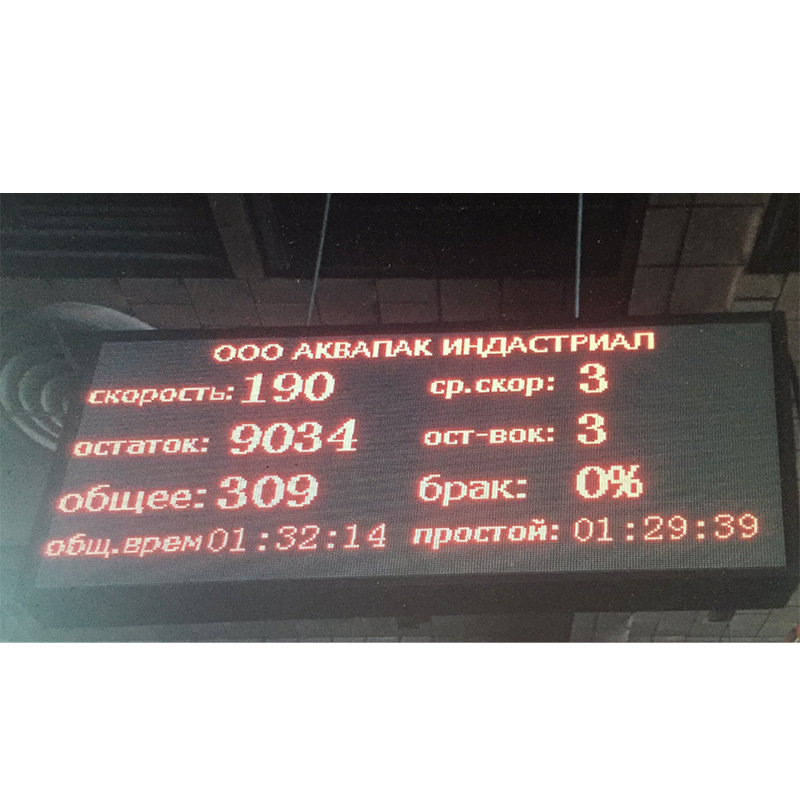

Double Side Display LCD

Real-time display of the current production of several meters, the remaining number of meters;

Real-time display of the current vehicle number, the average number of vehicles;

Configuration

Single facer control cabinet

Double facer control cabinet

Dry end control cabinet

Double side Display LCD

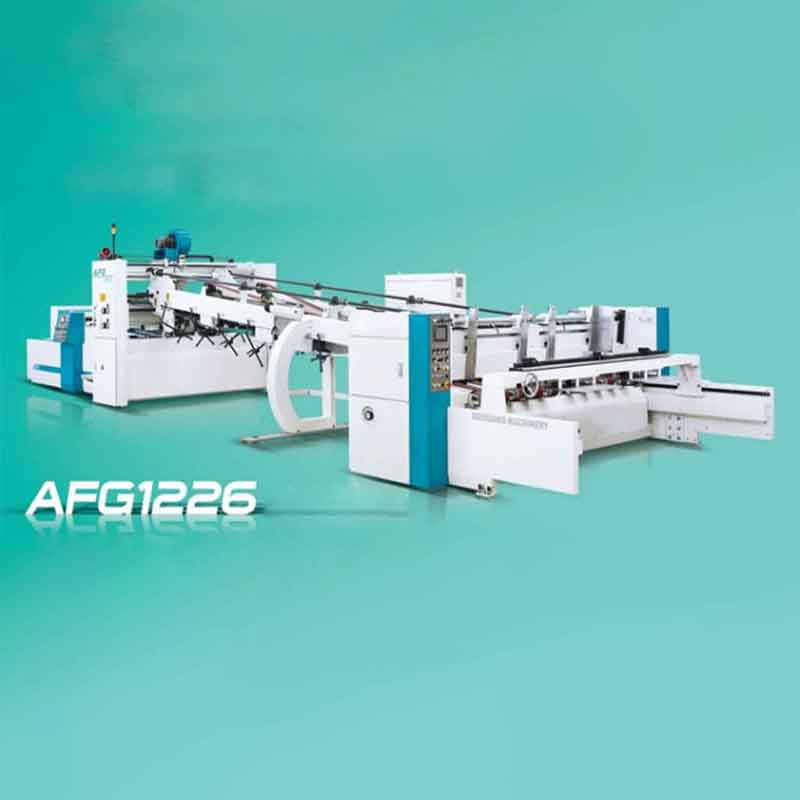

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Factory directly supply Scientific Inventory Control System Exercise Control - PMS and RFID paper roll storage management – GOJON , The product will supply to all over the world, such as: Bangladesh, Dubai, New York, With the technology as the core, develop and produce high-quality merchandise according to the diverse needs of the market. With this concept,the company will continue to develop merchandise with high added values and continuously improve items,and will present many customers with the best goods and services!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!