Manufacturing Companies for Conveyor Chute - Board Chain – GOJON

Manufacturing Companies for Conveyor Chute - Board Chain – GOJON Detail:

Feature

The combination of the Board chain conveyor and the Rotation conveyor can flexibly transport the paper roll to the required position, and has a high efficiency, which greatly reduces the labor intensity and increases the flexibility of the entire paper roll conveyor system. The intelligent paper roll transport system is mainly responsible for the transportation and management of the roll paper needed in the corrugator line.

● Structure: it consists of multiple v-type chains, sprocket transmission mechanism and frame and pneumatic left and right kicker; v-shaped board chain consists of v-shaped plate and rolling bearing, v-shaped plate angle is 170 degrees, width is 250mm;

● Motor reducer: 2.2kw;

● Board chain speed: max 20m/min, frequency converter, can be reversed;

● Sprocket material: 45 steel, quenched after quenching and tempering;

● The bearing is FK brand, and the rack is made of lead-out and butter for easy maintenance;

● The gear oil of the geared motor is iso vg220 oil;

● Maximum load of single paper roll: 3 tons;

● After finish the basic frame and frame bracket, all of the equipment are directly installed on the site. After test, the cover plate is fixed with stainless steel screws and the frame bracket, which is convenient for post-assembly repair and maintenance;

Function

● Each section of the original cardboard chain conveyor can store 1 or 2 pcs of paper roll under static conditions. According to the signal from Corrugated line tract, the original paper is automatically kicked over, which is very helpful for improving the speed of the vehicle;

● Reduce the loss of the paper roll and reduce the running cost;

● Realize the unmanned automatic operation.

We are committed to the intelligent, efficient and customized logistics system of the corrugated board industry, and provide the most suitable solution for the upgrade of the intelligent logistics industry of corrugated factories worldwide.

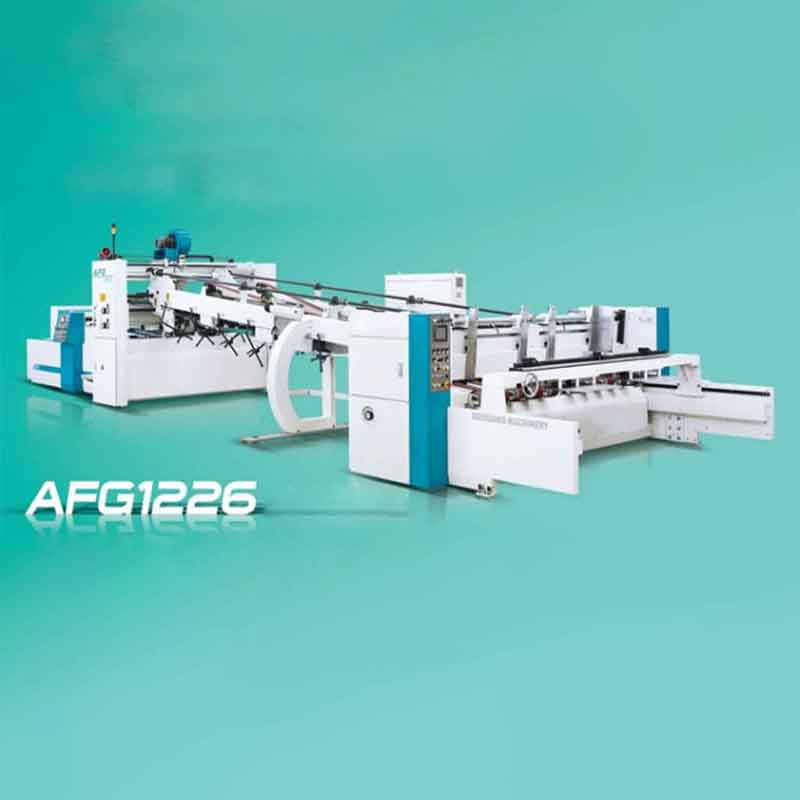

Layout of Main Equipment

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Manufacturing Companies for Conveyor Chute - Board Chain – GOJON , The product will supply to all over the world, such as: Chile, Accra, Belarus, With a wide range, good quality, reasonable prices and stylish designs, our solutions are extensively used in beauty and other industries. Our solutions are widely recognized and trusted by users and can meet continuously changing economic and social needs.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!