PMS and RFID Paper Roll Storage Management Corrugated line production management system

To get more details about Production Management System, pls visit here

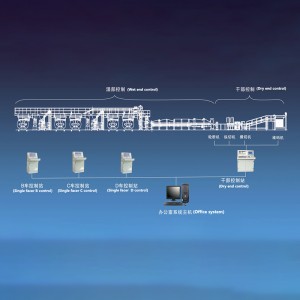

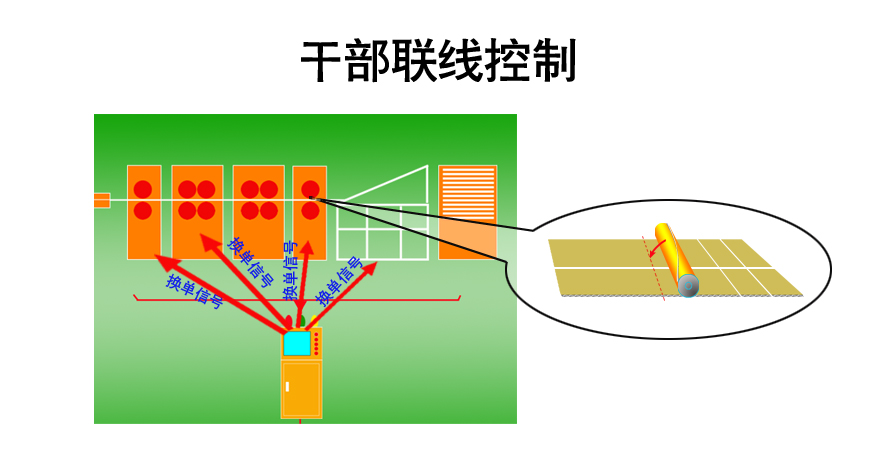

Dry end Online Control

At Corrugated production line Dry end side, the production management system can control the rotary cutoff, the slitter machine, the cutter machine and the stacker, and automatically send the orders downloaded from the office to the controllers online, completely avoid the personnel complicated orders input error, and reduce the quantity of bad paper boards when order change control not well.

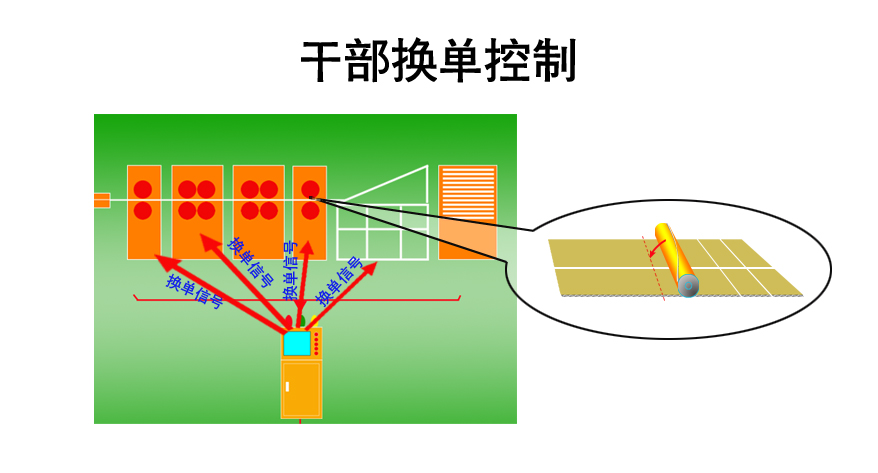

Dry end Order Change Control

Order change control: This is most important function, its action is not only in the appropriate time to start the individual order change program, at the same time, in order to coordinate orders separation and NC cutter speed above problem (NC cutter in different cutting length has different speed limit), Dry end need to automatic control to slow down its speed to the appropriate order change speed. After the automatic order change program finished, return to machine speed before change or the maximum speed limit. Example: artificial operation in NC slitter, pressure loss (up and down) generally within 5 meters. The production management can avoid loss of this part.

When connection equipment controller of Dry end, the controller as a whole the main control task, including bad paper control and order change time; The PMS of role is to constantly provide order data synchronization, recycling production as a result, at the same time, instant Dry end controller to capture the production status of orders, such as good paper, bad paper boards quantity to calculate and adjust the wet end paper use and paper mill change time.

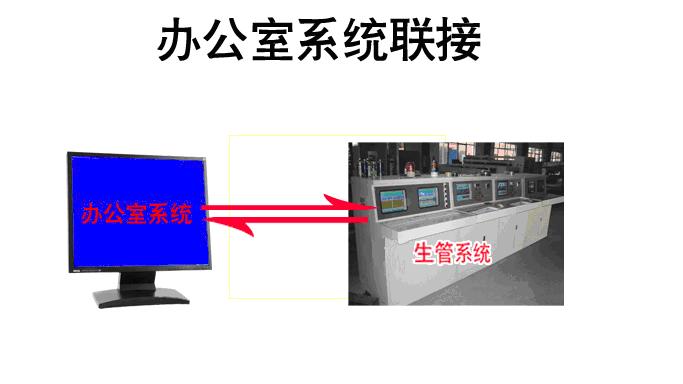

Office System Connection Online. (Optional)

PMS provide different kinds of ERP connection mode.including (RS-232 / RS-422) serial communication, also provide file exchange and delivery (FTP) way. So whether the customer is UNIX, SCO-UNIX, WINDOWS, DOS system, We have the experience and method to connect. The connection consists of three parts.

• Download orders to the PMS system

• Recycle production data from finished orders

• Real time corrugated line production data, written in ERP file

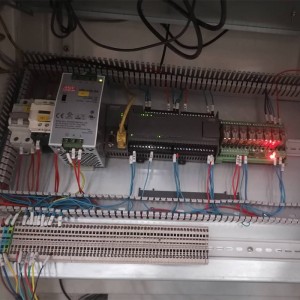

Dry end Control Cabinet

|

Item |

Description |

Quantity(pcs/set) |

|

1 |

Industry computer |

1 |

|

2 |

LCD display |

1 |

|

3 |

Simens PLC |

1 |

|

4 |

Keyboard 101 |

1 |

|

5 |

Control cabinet group for Dry end |

1 |

|

6 |

Control cabinet |

1 |

|

7 |

Industry function keypad |

1 |

|

8 |

Industry alarm device |

1 |

|

9 |

Controller for Dry end |

1 |

|

Features |

● Double facer speed remote control ● Date display of Last order production efficiency ● Date display of production efficiency present day ● Real time monitor of full line ● Not produced order details query ● Dry end control for machines connect ● Order insert, modify, delete, rearrange ● Production efficiency display of current order ● Real time monitor of full line production status ● Stock data display ● Speed, paper residual and statement display ● Shift setting |

|