Renewable Design for Automated Feeder - Automatic Quality Inspection machine Rejection machine of unqualified products Quality Inspection system – GOJON

Renewable Design for Automated Feeder - Automatic Quality Inspection machine Rejection machine of unqualified products Quality Inspection system – GOJON Detail:

In addition, the unqualified products after inspection can be rejected online, and the qualified cardboard, color box and color box can be automatically counted and stacked; the whole machine has more diverse changes, simple debugging, simple and convenient operation.

This machine is equipped with unique feeder bottom suction and bottom suction belt paper feeding. It adopts PLC operating system, and the transmission structure adopts single-group independent motor transmission, low noise, durable, and the upper belt pressure is pneumatically adjusted. Equipped with a high-power motor to complete the electric board adjustment, reduce loss, reduce labor, ensure product quality, and high efficiency, etc.

For carton and color box printing QR code and serial code solutions, they are installed on a dedicated mechanical platform. The printing system provides 54mm UV inkjet printers. The coding system prints UV inks.

Technical Parameters

Applicable paper quality: used for 1mm-8mm, three-layer, five-layer watermarked corrugated cardboard, offset printing color mounted corrugated cardboard; paper feeding method: correct and automatic continuous feeding

Mechanical speed (MAX): 160 m/min

Paper feeding range: 400-1400mm

Mechanical size: (L*W*H): 14000 mm*2310 mm*2135 mm

Max.product: 1400mm (transverse) * 1000mm (moving direction)

Min product:400 mm (transverse) * 400mm (moving direction)

Total weight (approximately): 10.5T

Maximum power: about 30KW (excluding air compressor)

Flatness: slightly warped (the height of corner warping is not more than 5mm);

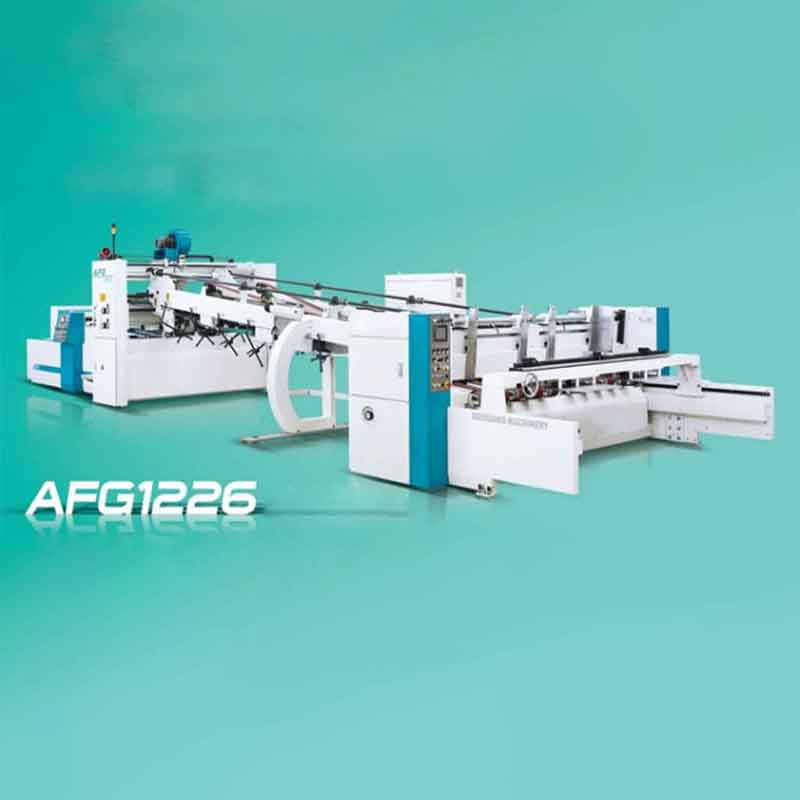

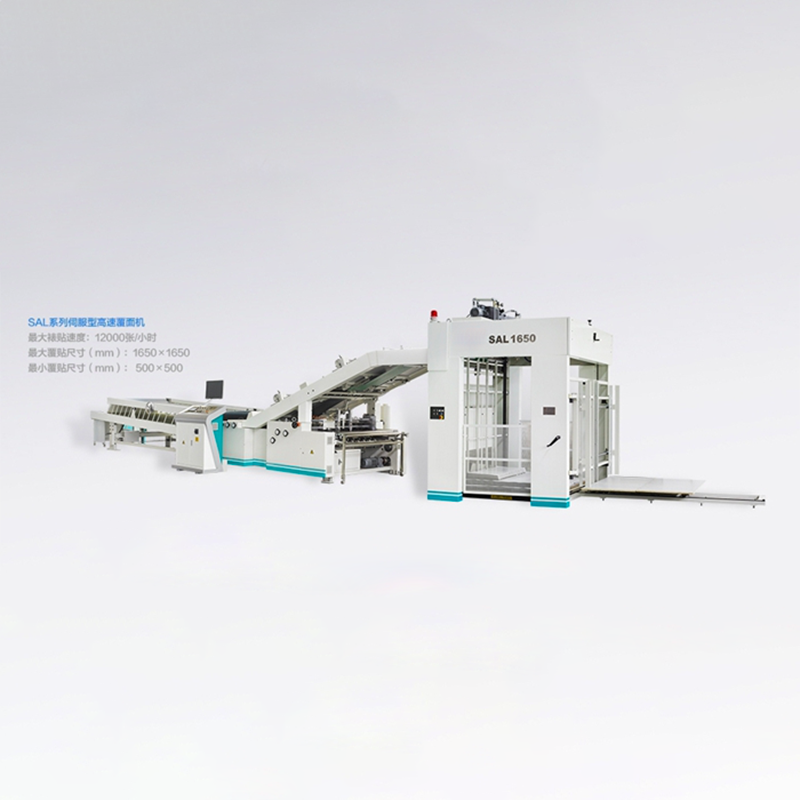

Product detail pictures:

Related Product Guide:

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for Renewable Design for Automated Feeder - Automatic Quality Inspection machine Rejection machine of unqualified products Quality Inspection system – GOJON , The product will supply to all over the world, such as: Uruguay, Sudan, Botswana, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!