Semi-Auto palletizer

To get more details about Auto Palletizer & Strapping&Wrapping line, pls visit here.

Technical parameter

|

No |

Name | Description |

| 1 | Lifting platform | hydraulic fixed scissor lifting platform, the rising speed is 3-5m/min, and the falling speed is adjustable |

| 2 | Platform | Telescopic Stainless Steel Panel |

| 3 | Manual finishing table | in the form of Universal wheel table |

| 4 | Pallet conveying system | pallet forklift travel and lift adopts chain mechanism, pallet travel is conveyed by modular belt conveyor |

| 5 | Modular belt sprocket | PP material overall processing |

| 6 | Conveyor belt | imported POM material module mesh belt, mesh belt thickness: 12mm |

| 7 | Equipment material | 10t steel plate laser processing |

| 8 | Mesh belt speed | Max30m/min (frequency conversion speed regulation) |

| 9 | Electric roller | 63.5*3 bright roller, galvanized surface, transmission mode is chain driven polyurethane friction wheel transmission |

| 10 | Motor power | conveying motor 1.5KW,Taiwan Wanxin brand |

| 11 | PLC | Siemens brand |

| 12 | Inverter | Siemens brand |

| 13 | Low voltage electrical | Schneider brand |

| 14 | Sensor | Omron brand |

| 15 | Appearance | Surface electrostatic spray |

Function

High efficient downstream processing system for modern carton box production line

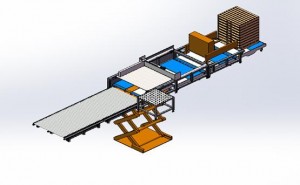

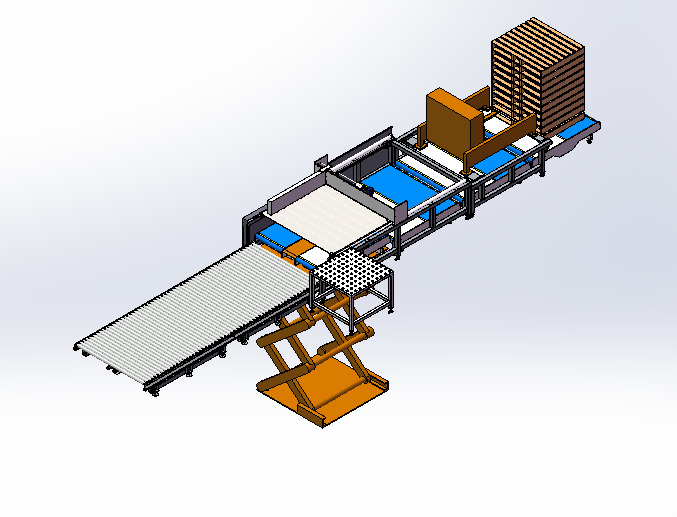

♦ Load former line

Process instruction

1. Place one whole groups of pallets on the rightmost module belt conveyor, the forklift travels and lifts from low to high the second pallet of whole pallets, lifts the pallet, and leaves the pallet on the module belt conveyor and transports it forward to the elevator position, the forklift falls and the remaining pallets are placed on the conveyor, and the forklift reset.

2. Transport another pallet to the modular belt conveyor in front of the elevator as a standby. After the pallet is stacked, it is conveyed forward, and the rear pallet is automatically conveyed. The rightmost module belt conveyor has a detection function. Continue to work after waiting for the next pallet to be placed.

3. Manually pick up the packaged cardboard and arrange it on the manual sorting platform, and place the cardboard on the elevator platform for stacking. After a layer of cardboard is stacked well, manually step on the foot switch, the panel is pulled back, and the elevator automatically drops the height of the stacking cardboard, then step on the foot switch, the platform is extended, and the next layer of stacking is carried out. The stacking height can be set in advance. When the stacking height reaches the specified height, the elevator automatically rises to the horizontal position, and the stacking cardboard rolls forward electrically. It can also be conveyed manually according to the stacking height.