Special NC Auto Feeder-Slitter Scorer-Stacker

To get more details about our Carton box Smart equipments, pls visit here

Function

As the important auxiliary equipment for corrugated line, it is used for slitting, scoring, counting and stacking of small-batch, multi-size cardboards. It adopts full computer control, high speed order change, automatic paper feeding, automatic counting and discharging.

Feature

• Auto servo leading edge feeder

1.Servo control feeding, which can adjust feed roller according to the length of the paperboard automatically, to achieve paper feeding stably for different lengths of paperboard. Prolong the length of Auto feeder,to feed the paper board in 3meters length.

2.The adjustable work platform with lower suction, the selected light pressure roller and the high-density pulley reduce the friction on the paperboard, so that the paper feeding is more stable and smooth.

3.Auto adjust the position of the side baffle, the rear baffle according to the width and length of the cardboard, and also has a manual fine adjustment function.

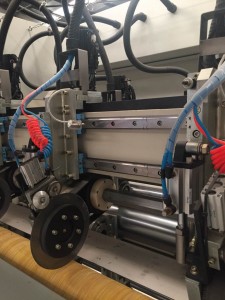

• NC full auto Servo thin blade slitter scorer

1、The gap between rubber roller and the height of the knife holder can be adjusted synchronously to ensure the strength of the cardboard;

2、The position of the cutter is automatically Zeroed and the Thin knife is made of ultra-thin tungsten alloy steel, which own long working life;

3、Patented order method, and order change time is 20-35 seconds, positioning accurate;

4、It adopts pneumatic/automatic lifting knife design, which is flexible in order and simple in operation;

5、Select high-quality steel, the rail beam adopts box-type welded structure, which improves the strength and stability of the whole machine;

• NC Auto counting Gantry Stacker

1、 Frequency conversion control two-segment belt, which is automatically adjusted according to the feeding speed.

2、 To prevent paper board from deviating, the Sun wheel presses and discharges the paper board at end of the output.

3、 Automatic control stacking height, laser detection of stacking height, and control of the drop between the gantry baffle and the paper discharge port, to ensure the best stacking effect.

4,The gantry baffle is adjusted automatically, positioned according to the length of the paper board, and lifted up and down automatically。

Tech.parameter

| Item | Specification |

| Slitting/scoring | 6 knife/ 10scorer |

| Max. Slitting width | 2800mm |

| Min Slitting width | 135mm |

| Min scoring width | 106mm |

| Through the thickness of the paper | 2-10mm |

| Min. feeding paper length | 360mm |

| Max stacking length | 3000mm |

| Work speed | 150m/min |

| Host computer | Industrial one machine, touchable operation |

| PLC | High performance FATEK PLC |

| Leading edge Drive | Servo motor 3KW |

| Leading edge Fan | 5.5kw(including silencer and air tube) |

| Order motor | Servo motor 0.75KW |

| Slitter drive motor | 5.5KW-6 |

| Discharge drive motor | Taiwan reducer 1.5kw |

| Gantry up and down | Turbine reducer 2.5KW-40S |

| Lengthways discharge motor | Gear reducer 1.5KW |

| Main drive inverter | Schneider |

| Low voltage electrical appliance | Schneider series |

| Main drive type | Adopt imported synchronous belt transmission device, stable, high precision, long service life, and low running noise |

| Size | L*W*H:11000×4280×2100mm |

| Total power | 26kw |